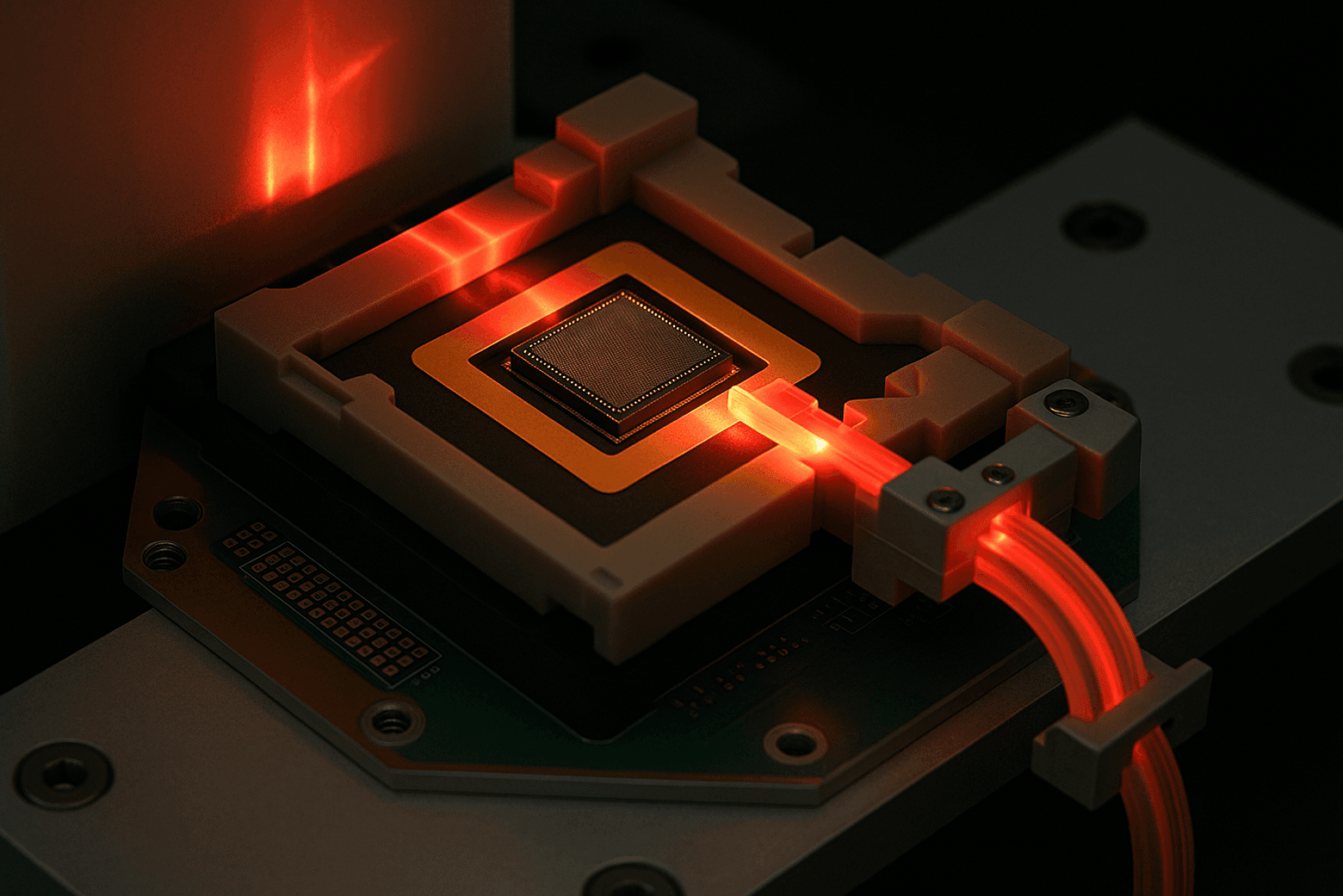

Quantum Computing

Nanoimprint Lithography (NIL) offers a scalable, high-precision platform for fabricating complex nanostructures critical to quantum computing and quantum sensing.

Our QtNIL hybrid-process solution enables the development of essential quantum components—including single-photon emitters, entangled-photon metasurfaces, nonlinear photonic waveguides, quantum dot resonators, and photonic crystal cavities—on heterogeneous material platforms with exceptional fidelity.

QtNIL solutions are ideal for quantum R&D labs, academic institutions, and next-generation quantum hardware developers seeking reliable, scalable nanofabrication with quantum-level precision.

Datacom/Telecom

As data transmission demands faster speed and higher energy efficiency, NIL offers a scalable solution for fabricating key photonic components—including waveguides, gratings, metasurfaces, and photonic crystals—with high precision and throughput across diverse substrates.

Our QtNIL enables the development of next-generation optical transceivers, silicon photonics, co-packaged optics (CPO), and high-density interconnects. Our solutions are ideal for companies and R&D teams at the forefront of data infrastructure, where precision, scalability, and customization are essential.

Illumination

QtNIL’s hybrid NIL platform enables precise integration of nano-optical structures into compact, low-power broadband light sources used in biomedical spectroscopy, point-of-care diagnostics, optical biosensors, and lab-on-chip systems. Our process supports high-fidelity fabrication on polymers, glass, and other biocompatible materials, enabling light engines with enhanced color purity and beam control.

QtNIL solutions are ideal for medical device manufacturers, biophotonics researchers, and companies developing next-generation miniaturized diagnostic tools that require highly functional, precision-engineered optical engines in small form factors.

Optics

QtNIL enables high-precision, scalable fabrication of nano-optical components such as waveguide couplers, diffractive optical elements (DOEs), metalenses, and wafer-level optics arrays.

With our hybrid NIL process, we support the development of compact and lightweight optics essential for AR/VR headsets and immersive display systems. QtNIL solutions are ideal for compact optical module developers, AR/VR hardware manufacturers, and research teams working on next-generation visual technologies.

Advanced Sensing

QtNIL’s hybrid nanoimprint lithography (NIL) technology enables scalable, high-resolution fabrication of nano-optical components essential to autonomous vehicles and robotics. Our platform supports the production of beam-shaping optics, metasurfaces, and integrated nano-sensors that enhance core functions such as LIDAR, depth sensing, angle-resolved imaging and multispectral sensing.

These miniaturized and customizable optical structures significantly improve detection accuracy, energy efficiency, and form factor—making them ideal for next-generation autonomous platforms, drones, and AI-driven robotic systems. QtNIL collaborates with customers and research teams pushing the limits of advanced perception systems in real-world environments.

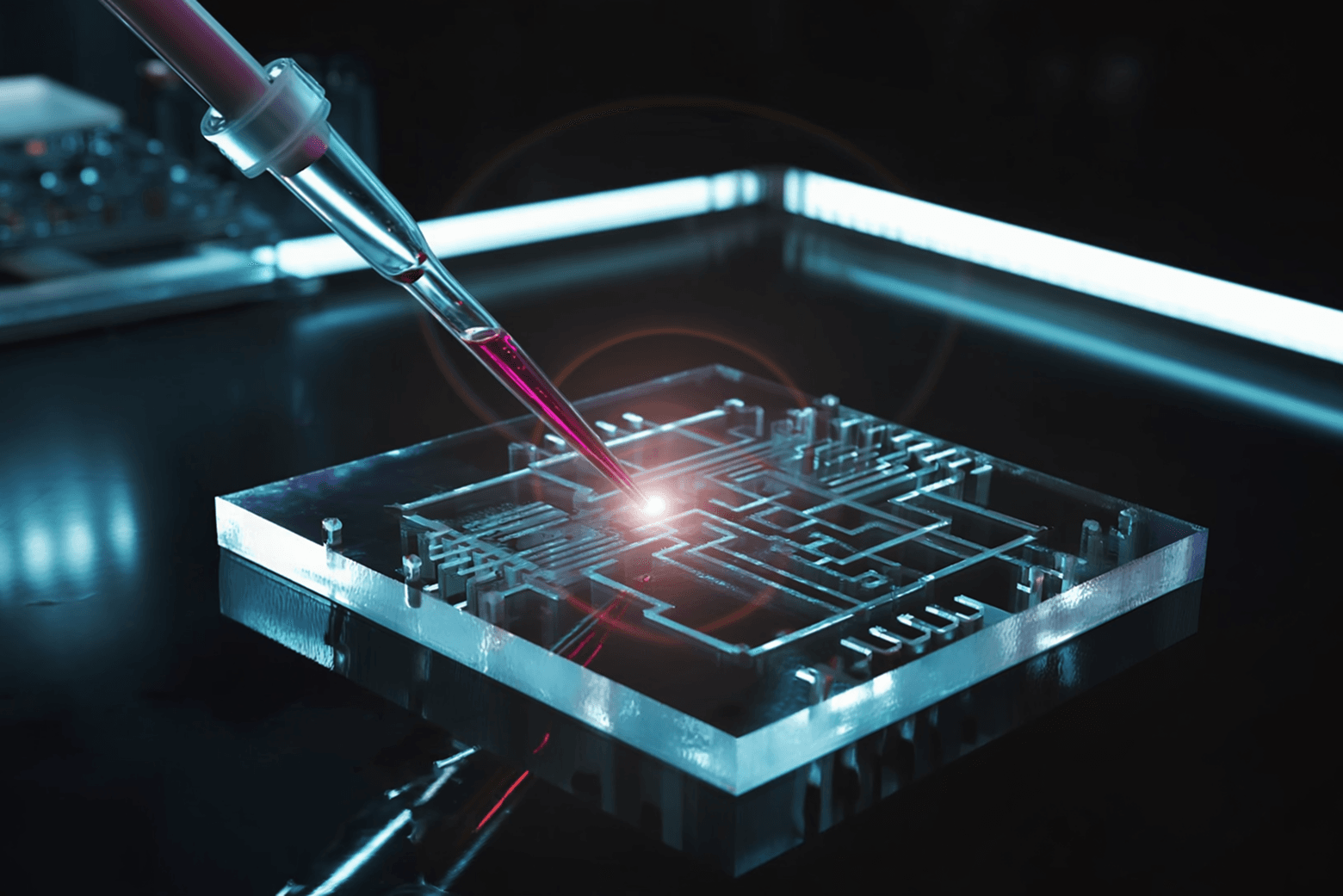

Bio Chip

QtNIL’s hybrid NIL platform enables high-resolution patterning of biocompatible nanostructures on polymers, glass, and flexible substrates—ideal for lab-on-chip, organ-on-chip, and advanced cell culture systems. These nano-features guide cell growth, adhesion, and differentiation.

With precise control over feature size, geometry, and surface properties, QtNIL supports scalable production of biochips, biosensor interfaces, and tissue scaffolds for applications in regenerative medicine, drug screening, and cell-based assays.