How Nanoimprint Lithography (NIL) Works

The process flow behind nano-scale patterning

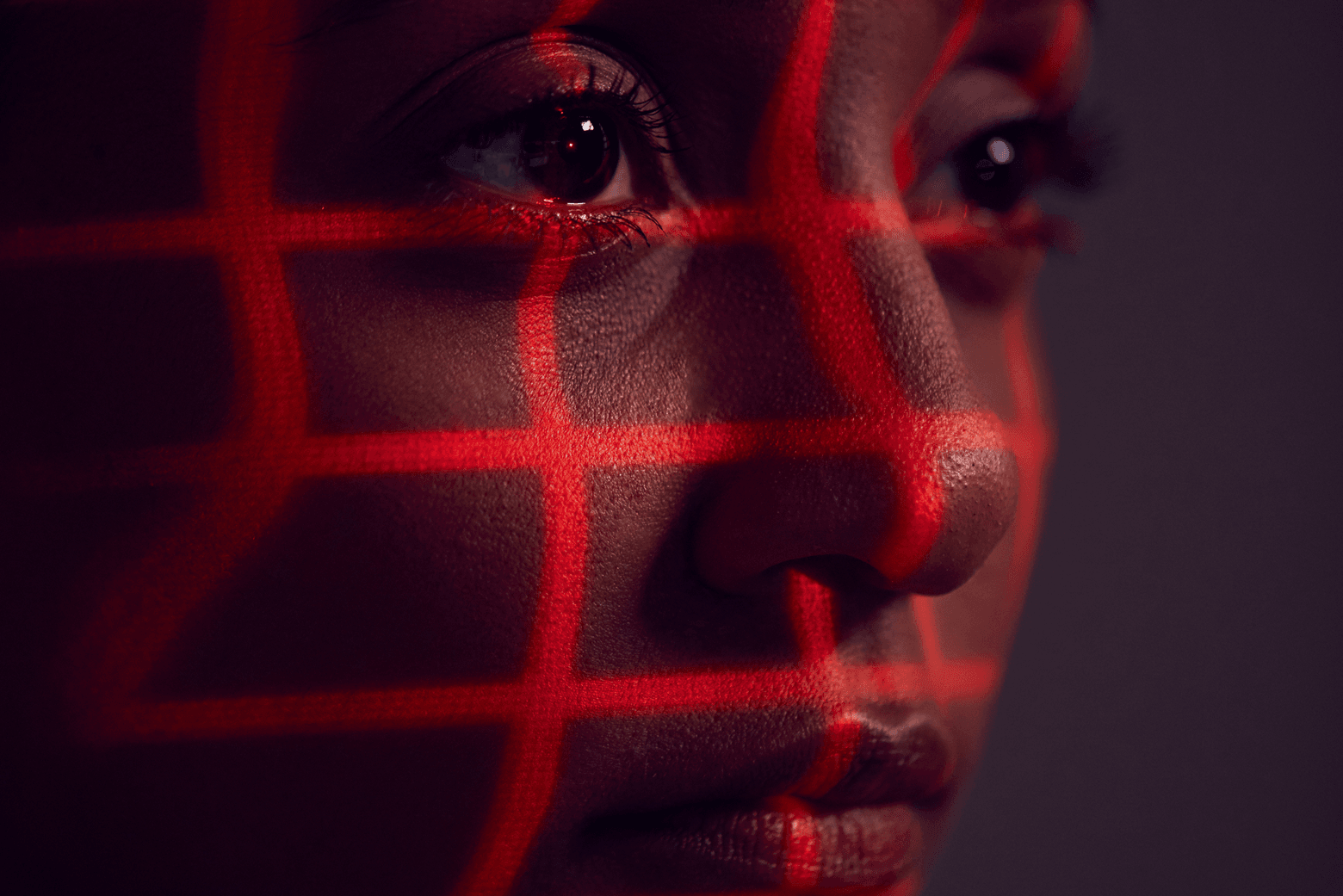

Application Domains

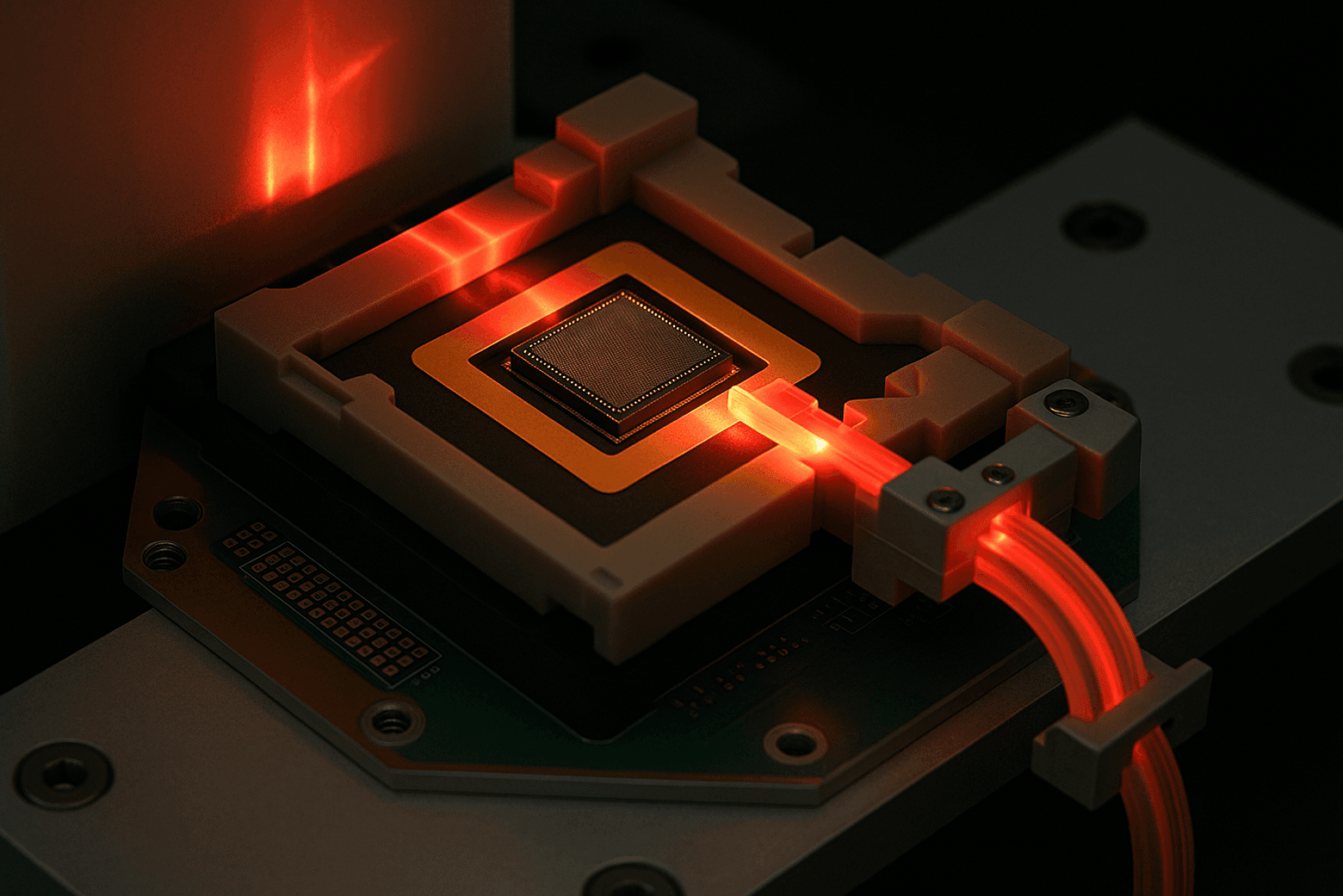

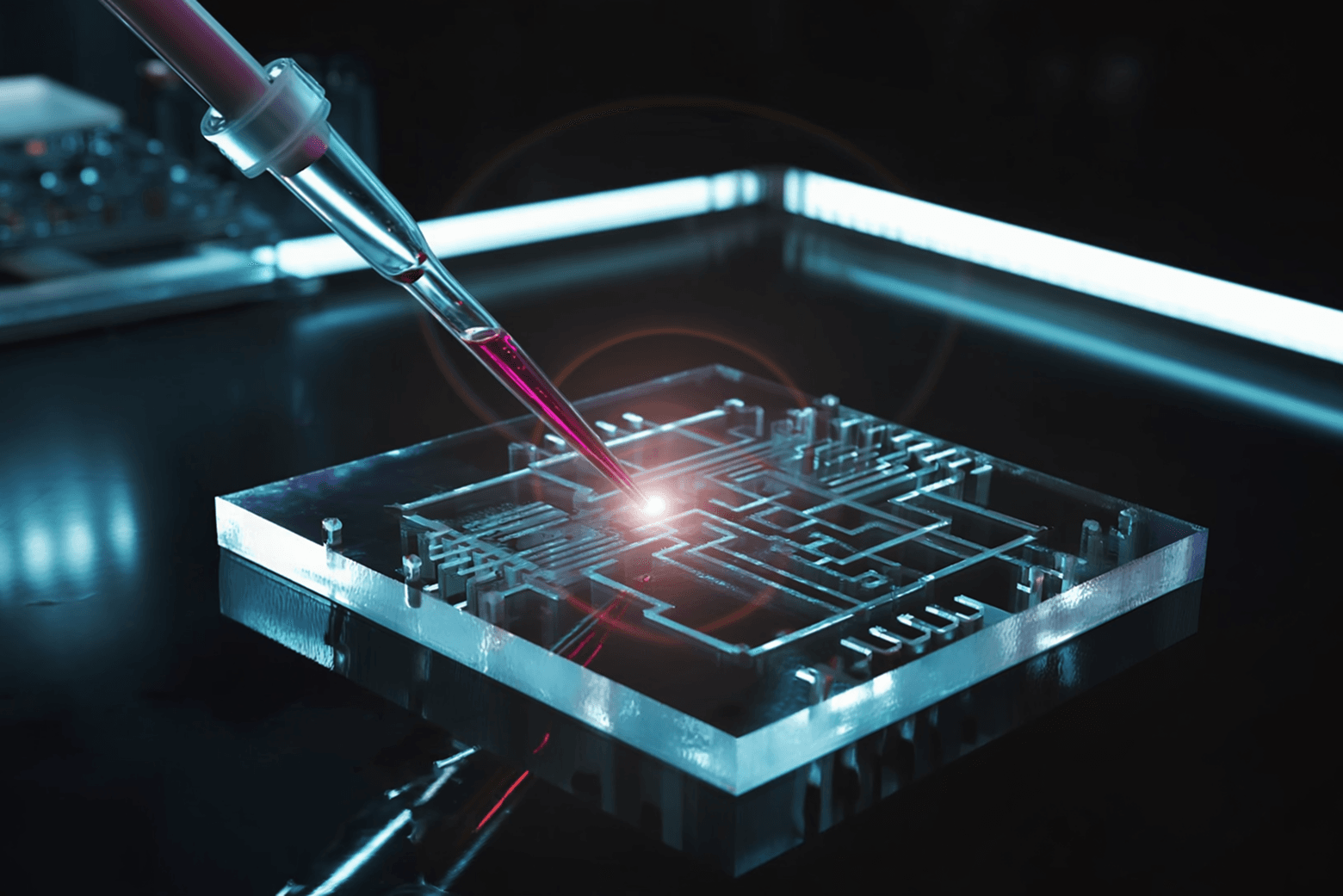

Nanoimprint Lithography (NIL) is a high-precision technique that stamps nanoscale patterns onto surfaces using a patterned mold. It offers a cost effective, high-resolution alternative to traditional photolithography for creating fine structures. NIL is ideal for producing nanochips, sensors, and optical devices. Its simplicity and accuracy make it perfect for industries requiring fine surface patterns at scale.

Our Team

With two decades of expertise in Nanoimprint Lithography (NIL), our team has developed world-class process technologies tailored to advanced manufacturing needs. We've successfully integrated nanoscale structures into industry-standard workflows, including high-volume LED wafers, hard sapphire substrates, and delicate InP laser wafers. Leveraging deep technical know-how and extensive production experience, we deliver highly customized fine structures across a wide range of materials. As we continue to push the limits of NIL, our capabilities are advancing toward next-generation quantum applications.

Overview of Quantum NIL’s Manufacturing Scope

Foundry of Hybrid Nanoimprint Lithography Solution for Material Engineering

Our foundry business is strategically focused on serving customers who require high-precision nanostructure fabrication at scale. This includes innovators in photonics, micro/nano-LED, meta-optics, advanced sensors and quantum devices. In addition, we support emerging applications in biomedical chips, AI-driven sensing technologies, and next-generation unmanned & robot systems.

We collaborate with startups, research institutions, and industry leaders who demand reliable, high-yield NIL production with deep customization capabilities. By offering scalable, application-driven solutions, we aim to accelerate the commercialization of breakthrough technologies across diverse industries.

NANO-FABRICATION FOUNDRY SERVICE

Grating Fabrication for DFB/VCSEL Epitaxy Wafer

Diffractive Optical Element (DOE) & Metalens

Photonic Crystal Fabrication

Customized Nano-Textured Hybrid Fabrication

SERVICE TECHNIQUES & SPECIFICATIONS

(2" ~ 8" wafer size)Production Scale of NIL (2" ~ 8" wafer size)

- Minimum CD in production: 25nm

- Fragile & bowling wafers can be applied

- Workable thickness of wafers: 75 µm ~ 2mm

& Photo LithographyE-beam Lithography & Photo Lithography

- High-end E-beam tool for NIL mold/master fabrication

- Process alignment mark fabrication by both of NIL and photo-litho

- Crystalline alignment along the major flat of wafers: <0.02°

- Dedicated dry etch tools for different materials

- Dry etch thickness variation within wafers: ± 3nm

- Possesses both of dry and wet etch

& SimulationNano-structure Design & Simulation

- PWE & FDTD self-developed codes

- Wavefront engineering designs

- Photon block & diffracted mode simulation